Polypropylene (PP)

This low cost resin in a homopolymer, copolymer, and random copolymer form is plastic injection molded by Rebling for many unique applications. Typical reasons for choosing polypropylene are cost; chemical resistance; electrical insulating properties; translucence and “live hinge” applications. Rebling molds polypropylene for several end use applications including protective caps for electrical contacts; battery housings; and small containers that rely on the “live hinge” capabilities of polypropylene.

This low cost resin in a homopolymer, copolymer, and random copolymer form is plastic injection molded by Rebling for many unique applications. Typical reasons for choosing polypropylene are cost; chemical resistance; electrical insulating properties; translucence and “live hinge” applications. Rebling molds polypropylene for several end use applications including protective caps for electrical contacts; battery housings; and small containers that rely on the “live hinge” capabilities of polypropylene.

Properties of Polypropylene plastic

The chemical resistance of polypropylene is outstanding. It is unaffected by dilute and concentrated mineral acids and bases, inorganic salts, solvents, and higher molecular weight aliphatics. Chlorinated hydrocarbons will cause them to swell and soften. Polypropylene is, however, attacked by halogens and other strong oxidizing agents.

Polypropylene is available in many grades including glass and /or mineral filled resins; homopolymer and random copolymer versions; flame retardant grades and specialty grades. The material in its natural state is translucent and can be molded in an unlimited number of colors. Polypropylene is also available in many melt flow rates ranging from less than 1 to over 60 g/10min. As the melt flow increases, the ability to mold thin wall parts increases while the mechanical properties of polypropylene exhibit some reduction.

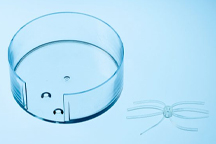

The copolymer versions of polypropylene offer enhanced mechanical properties at low temperatures, particularly impact strength. Live hinge applications such as a box and lid connected through a thin web of plastic that is flexed each time the lid is opened or closed are typically designed with polypropylene. Due to its high fatigue resistance, polypropylene is the ideal candidate for these applications as it can withstand the repetitive stresses of flexing the hinge when the lid is installed on the attached box. When molding a part with a “live hinge” feature, the optimum hinge life will be developed if the part is flexed to orient the molecular structure of polypropylene while the part is still warm from the molding cycle. Rebling utilizes post molding fixtures to orient the molecular structure of polypropylene. Gate location is also critical for a live hinge design. In general, the gate location should allow the melt front of the material to be parallel to the hinge.

The Homopolymer grades of polypropylene when compared to the Random Copolymer grades offer higher stiffness and strength as noted by the flexural modulus and tensile strength of the materials. The impact strength of the homopolymer grades however is not as high as those of the random copolymer.

The heat resistance of polypropylene makes it suitable for applications where autoclaving is required such as medical or laboratory instruments. It typically has a melting point of over 300°F. The chemical resistance and translucence of this material also are key factors in selecting polypropylene for food and beverage containers. Many of these containers are recycled and the resin identification code for this material looks like this:

Secondary Operations for Polypropylene plastic parts

Polypropylene is available in many extruded shapes such as bars, rods & tubing. Parts can be easily fabricated from these extrusions using standard metal working tools. Rebling is able to provide a full range of secondary operations, such as turning, drilling, tapping, and grinding, as well as ultrasonic insertion, ultrasonic welding, pad printing, and assembly.

Thermoplastic

Thermoplastic ABS

ABS Acetal

Acetal Acrylic

Acrylic EMI

EMI Noryl (PPO)

Noryl (PPO) Nylon (Polyamide)

Nylon (Polyamide) Polybutylene Terephtalate (PBT)

Polybutylene Terephtalate (PBT) Polyether Ether Ketone (PEEK)

Polyether Ether Ketone (PEEK) Polycarbonate (PC)

Polycarbonate (PC) Polyethylene (PE)

Polyethylene (PE) Polyphenylene

Polyphenylene Polypropylene (PP)

Polypropylene (PP) Polystyrene (PS)

Polystyrene (PS) Polysulfone (PSU)

Polysulfone (PSU) Thermoplastic Elastomers

Thermoplastic Elastomers UHMW

UHMW Polyetherimide (Ultem)

Polyetherimide (Ultem)